Customer presentation

The customer, the ICT(1) department of Infrabel (website), is the Belgian railway company that owns and manages the entire territory’s infrastructure. In a few figures, the railway infrastructure represents 3,500 kilometers of railway tracks, around 12,000 switches and nearly 2,000 level crossings.

Several rail operators use Infrabel’s infrastructure for a total of 110 million train-kilometers. Infrabel employs 9,924 people and produces 27.8 GWh of renewable energy (with photovoltaics and wind turbines).

Customer requirements

Infrabel has many critical loads to secure:

- Along the tracks: Level crossing barriers,

- Inside stations: Signaling equipment (IT servers and switches),

- Along the train platforms: ticketing system, screens (passenger communication) and sound system.

To secure all these loads, Infrabel asked CE+T for a solution with a mix of rectifiers and inverters. The complete solution consists of converters, power distribution, circuit breakers, monitoring and batteries. The required autonomy may vary from one site to another but is between 2 and 8 hours.

Our previous solution

CE+T Power has been offering and installing an integrated solution for many years comprising:

- Nova modular inverters (produced by CE+T) and its monitoring,

- Cordex rectifiers (produced by Alpha) and its monitoring,

- Power distribution and circuit breakers,

- Batteries with two chemistries: LIFEPO and VRLA (Valve-Regulated Lead-Acid).

Customer issues

This solution was not ideal for several reasons:

- Changes in customer loads: The type of loads to be secured (AC or DC) was changing quite often. Consequently, Infrabel had to modify the number of Nova inverters and/or Cordex rectifiers in order to change it along with the loads. If there were enough empty slots in the shelves, adding power was really easy because Nova and Cordex are plug & play modular converters. But in case of space shortage, the operators had to switch to bypass mode to be able to add a shelf, make all the connections and then plug in the new converters.

- Inventory management: Inverters and rectifiers have their own monitoring solution. At the end of the day, Infrabel had four types of components to keep in stock (1 inverter, 1 rectifier and 2 monitorings).

- Trainings: The use of components provided by different manufacturers is always more complex. The way the electric connections are designed, or monitoring needs to be configured for example, is not the same. Consequently, the training for operators is more complex.

For all these reasons, Infrabel asked CE+T to offer a new solution based on the innovative Sierra module.

Our solution: Sierra bi-directional technology

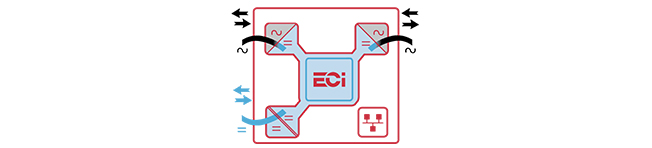

At the heart of the proposed solutions, there is the Sierra module. This unique building block acts both as inverter and rectifier. The power converter is made up of three ports that function as both an input as well as an output. The illustration here shows the module topology and these three ports (two AC ports on top and one DC port at the bottom).

The main advantage of this solution is its ability to secure AC and DC loads as well as charging batteries at the same time. To do this, the module automatically manages the power source (coming from the AC port at the top left) and distributes it wherever it is needed; on the AC port at the top right for AC loads or on the DC port at the bottom for DC loads and batteries. In case of a power outage, the power flows from the batteries to the DC loads but also to the AC loads through the module.

The main advantage of this solution is its ability to secure AC and DC loads as well as charging batteries at the same time. To do this, the module automatically manages the power source (coming from the AC port at the top left) and distributes it wherever it is needed; on the AC port at the top right for AC loads or on the DC port at the bottom for DC loads and batteries. In case of a power outage, the power flows from the batteries to the DC loads but also to the AC loads through the module.

Solution: Description

Shelf overview

- You can plug up to 5 x Sierra modules in a single shelf,

- You can plug up to 4 x Sierra modules in a singles shelf if you add the Inview S Slot monitoring (as per picture enclosed).

- Each Sierra 10 – 48/230 can secure up to 1.2 kW (1 kW maximum in full AC or DC mode) loads. You can read more about this power converter here.

System overview

Below you can find a single-line diagram representing this solution:

- 4 x Sierra modules (represented by the technology illustration) plus the monitoring in a shelf,

- Measure Box at the bottom for additional DC measurements,

- The grid, on the left (Q21), connected to each AC port of the modules,

- Power distribution for batteries (Q39 and Q40) and DC loads (Q41 to Q50) on the right,

- Power distribution for AC loads at the top right.

Shelf electrical cabling

Advantages

Advantage 1: UPTIME

By using a single module for AC and DC loads, you can add more redundancy at a reasonable cost. For example, if you want N+1 redundancy with a mix of inverters and rectifiers, you will have to add two modules. With the Sierra module, only one is required. On a single shelf the direct impact is already big, but if you look at the infrastructure level with hundreds of sites, the impact is huge!

In addition to this feature, only available with the Sierra, uptime is also guaranteed by the patented ECI technology built into all CE+T converters:

- Instant switching from the grid to the batteries, in the event of a power outage (using the internal DC buffer),

- Pure sine wave (using AC input to power AC loads with 96% conversion efficiency),

- Galvanic insulation between AC and DC

- No Master / Slave configuration,

- Redundant communication Bus.

Together, these features ensure the highest level of reliability and availability while keeping investment costs low.

Advantage 2: QUICK & EASY UPGRADE

When developing a new solution, it is important to consider the customer’s current situation. Infrabel has many inverters and rectifiers in the field. It is not reasonable to replace all of these backup solutions immediately.

For this reason, the new Sierra solution has been designed to easily replace old shelves with the new ones. All previous elements can be kept (cabinets, batteries, etc.). Of course, for Infrabel, this represents huge savings in terms of investment because each change is a direct cost in terms of material and human labor.

Advantage 3: PLUG & PLAY

To further facilitate the installation of these new shelves, CE+T has designed a power distribution accessory. Screwed at the rear of the shelves, this accessory includes quick AC connectors (maximum 63A), quick DC connectors and the ability to attach an Ethernet cable to connect to the Measure Box:

Complete wiring can be done with a standard flat screwdriver.

The modules are also hot-swappable. You can therefore unplug or plug new modules while the system is running. No configuration is required; the new module automatically learns the settings of the others. Modules can be changed by anyone within the company. It guarantees a fast and reliable repair process in the event of a failure.

Advantage 4: FLEXIBILITY

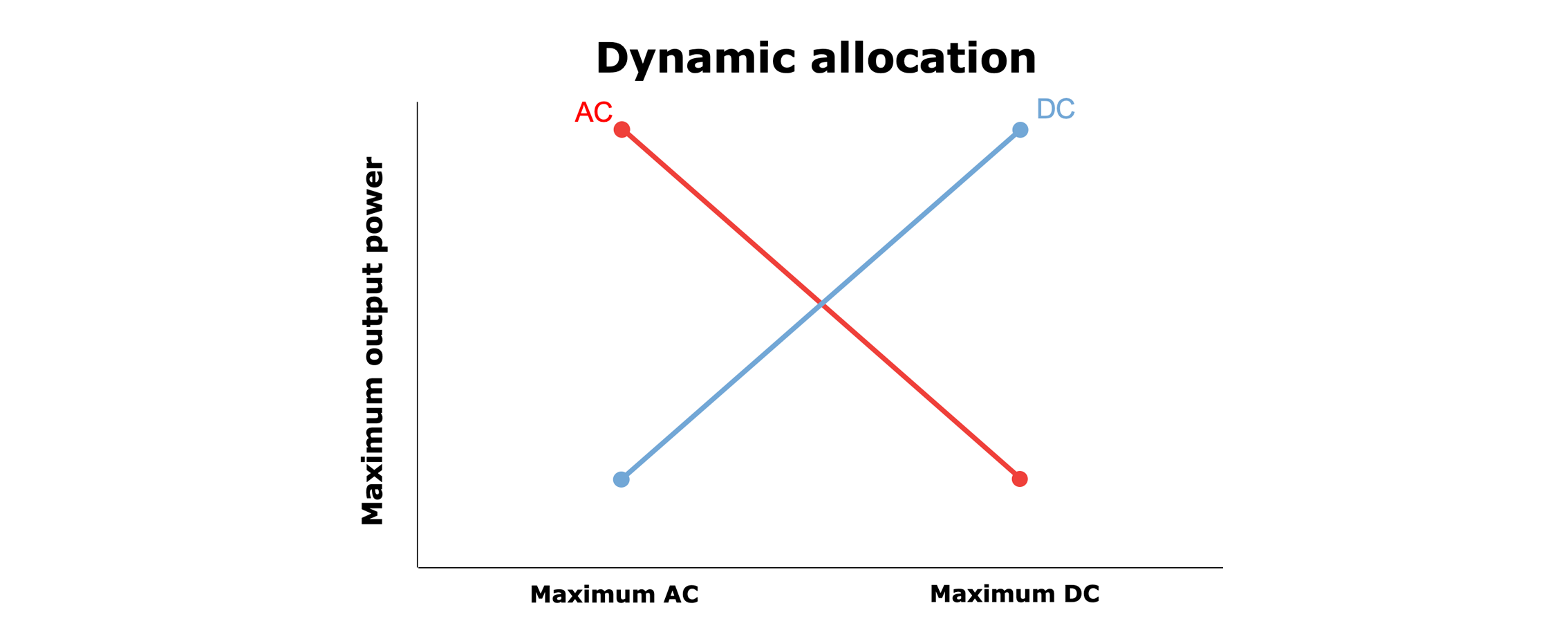

As explained earlier in this document, one of the customer’s issues was related to changes in the mix between AC and DC loads. The Sierra actually works using another method. The sources (in this case, the grid), fill the DC buffers built into each Sierra module. This power is then distributed wherever it is required; AC loads, DC loads or batteries. If the buffer becomes empty, the module naturally consumes more power from the grid. And if the grid is longer available, it will discharge the batteries. We call this a “dynamic allocation”:

The Sierra does not require any setup or configuration to do this. Just change your loads and the Sierra will adapt itself automatically. If the power increases, all you have to do is to connect a new module in an empty slot in the self and you will have 1 kW more. Plug another one for an additional kW, etc.

Advantage 5: COMPACTNESS

In the image below, you can see the comparison between the previous and the new solution:

In other words, the difference between the two solutions is an increase of 85% in power density with the same redundancy (N+1) and by using only one single type of module (less spares).

On top, for several sites, the Sierra solutions allow to avoid one extra shelf.

Let us consider a site where the customer needs:

- 8 kW of DC loads : 4+1 modules plus the monitoring = Two (2) shelves,

- 1 kW of AC loads : 2+1 modules plus the monitoring = One (1) shelf.

This means with previous solution = Three shelves in total.

The same can be done with the Sierra with 7+1 modules plus the monitoring = Two shelves in total.

Conclusion

In this case study, you have seen a detailed presentation on how CE+T can simplify the daily life of an end user. From installation to replacement, including the entire life of the system (maintenance, repairs, inventory management, etc.), we described how we can significantly improve the situation.

Ultimately, Infrabel will now benefit from increased uptime, a quick and easy upgrade (from the previous solution to the Sierra), a true plug & play solution, high flexibility in terms of power and AC/DC ratio and finally the compactness of the solution.

To achieve this, CE+T uses innovative and standard power converter modules ready to be integrated into personalized “packaging” (shelves, sub racks, cabinets, outdoor enclosures, etc.). In this way, the proposed solutions can perfectly meet the customer’s requirements.

In addition to this Sierra 10, CE+T also offer the Sierra 25 for higher loads (2.7 kW per module). We can also interface with other battery chemistries and offer many other features such as PMS (power management system), preventive maintenance, remote monitoring, phase balancing, etc. For this customer, the phase balancing offered by Sierra allowed the customer to limit breakers and distribution size.

Do not hesitate to tell us more about your specific case and we will be happy to find the best solution for you!

(1) ICT: Information and Communication Technology